In the bustling industrial landscape of Shanghai lies the Shanghai Tesla Gigafactory, a cornerstone of innovation in the electric vehicle (EV) sector. At the heart of this technological marvel lies a critical component: Songjiang metal hoses. These meticulously crafted hoses play a pivotal role in ensuring the seamless operation of various systems within the Gigafactory, ultimately enhancing efficiency and reliability in EV production.

The Shanghai Tesla Gigafactory stands as a testament to the monumental strides made in sustainable transportation. Established in 2018, this state-of-the-art facility has been at the forefront of EV manufacturing, boasting an annual production capacity of 250,000 vehicles, including the renowned Model 3 series. As Tesla’s first Gigafactory outside the United States, its significance transcends borders, symbolizing a global shift towards cleaner, greener mobility solutions.

Within this sprawling complex, Songjiang metal hoses emerge as unsung heroes, facilitating the smooth functioning of essential systems. From hydraulic circuits powering brakes and suspension to cooling systems safeguarding batteries and electric motors, these hoses serve as lifelines, ensuring uninterrupted operations. Their robust construction and flexible design enable them to withstand high pressures and temperatures, making them indispensable in the demanding environment of EV production.

Moreover, Songjiang metal hoses offer a sustainable alternative to traditional fuel systems, aligning perfectly with Tesla’s vision of a carbon-neutral future. By eliminating the need for fossil fuels and minimizing environmental impact, these hoses contribute to the Gigafactory’s overarching goal of sustainability. Their reliability and longevity further underscore their value, reducing maintenance costs and downtime, thereby optimizing production efficiency.

In the pursuit of excellence, Shanghai Tesla continuously seeks to enhance its operations. With Songjiang metal hoses at the forefront, the Gigafactory remains poised to meet the evolving demands of the EV market. Their versatility extends beyond conventional applications, offering solutions for vibration and shock absorption, further enhancing vehicle performance and passenger comfort.

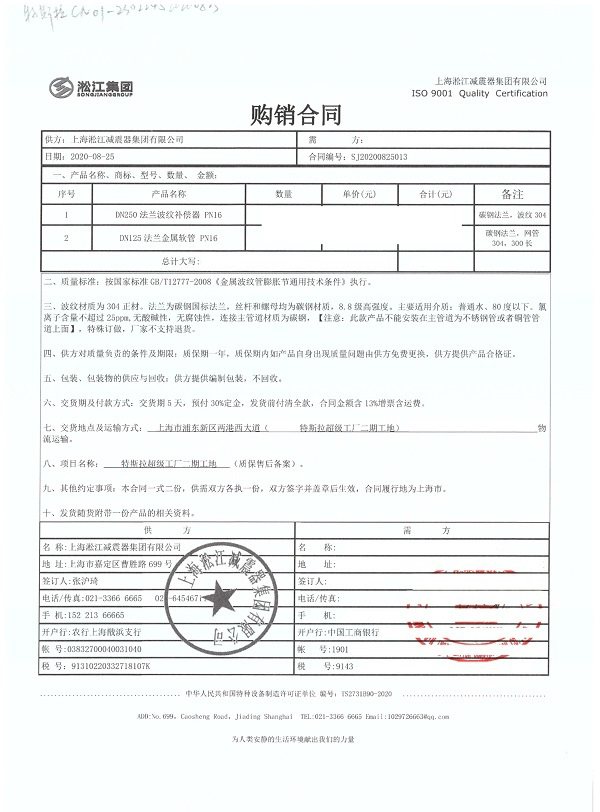

Below is a scanned copy of the authentic contract. Please do not modify or reproduce it. This contract serves as proof of supply. Thank you for your cooperation.

In conclusion, Songjiang metal hoses epitomize innovation and reliability in the dynamic landscape of Shanghai Tesla Gigafactory. As the automotive industry embraces the transition to electrification, these hoses serve as pillars of support, enabling the realization of Tesla’s vision for sustainable mobility. With their proven track record and unmatched performance, Songjiang metal hoses stand as a beacon of excellence, driving the future of electric vehicle production forward.

Related links:Stainless Steel Pipeline Expansion Joint “with excellent flexibility”

If the original article is reprinted, please indicate the link of this article:https://www.pipeline-expansion-joint.com/enhancing-efficiency-and-reliability-songjiang-metal-hoses-in-shanghai-tesla-gigafactory.html

![[PTFE] Pipeline Expansion Joint “High lubricating and non-sticky”](https://pipeline-expansion-joint.com/wp-content/uploads/2022/05/PTFE-Pipeline-Expansion-Joint-Photo.jpg)