How to use and Install the Pipeline rubber bellows for pipes?

1. When installing flexible Pipeline rubber bellow in the pipeline, it must be in a natural state and do not artificially deform the product. When the pipeline medium is resistant to acid and alkali, oil, high temperature and other special materials, a joint with a gear higher than the working pressure of the pipeline should be selected.

2. The flange connecting the Pipeline rubber bellow should be the valve flange

3. The normal applicable medium for flexible Pipeline rubber bellow is ordinary water with a temperature of 0-60°C. For special mediums such as oil, acid and alkali, high temperature and other corrosive and hard textures, the corresponding special resistance should be used. Material Pipeline rubber bellow, not blindly used or universal.

4. When the flexible rubber soft joint is used at the inlet and outlet of the pump, it should be located on the side of the water spring, and a metal reducing joint should be installed between the water spring and the large diameter source of the reducing diameter.

5. When the displacement of the pipeline is greater than or equal to the large compensation amount of the joint, the number of joints should be increased to parallel the displacement. It is strictly forbidden to adjust the deviation of the pipeline, so that the joint is in a state of extreme flexural displacement and deviation, and cannot exceed the limit ( expansion, displacement, deflection, etc.), please refer to the table below for specific installation data.

6. For high-rise water supply or suspended water supply, the pipeline should be fixed on the hanger, bracket or anchor frame, and the joint should not be allowed to bear the weight and axial force of the pipeline, otherwise the joint should be equipped with an anti-pull device (the bearing capacity must be greater than that of the pipeline) axial force).

7. When installing the rubber bellows , the screw rod of the bolt should extend to the outside of the joint, and the bolts on the end face of each flange should be repeatedly and evenly tightened by means of diagonal pressure to prevent pressure deviation. Threaded joints should be tightened uniformly with a standard wrench. Do not use afterburning stalks to make the joints slippery, slippery and break, and should be checked regularly to avoid loosening and causing slippage or water seepage.

8. After the rubber soft joint is under pressure for the first time (such as installation pressure test, etc.) or before it is reactivated after long-term disuse, the bolts should be re-pressurized and tightened before being put into operation.

9. When using or storing rubber soft joints, avoid high temperature, ozone oil and acid-base environment. A sunshade frame should be built for pipes used outdoors or in the sun and wind, and it is strictly forbidden to be exposed to rain, rain and wind. The surface of the joint is strictly prohibited to be painted and wrapped with thermal insulation materials. Due to the aging problem of rubber products, it should be checked and replaced in time.

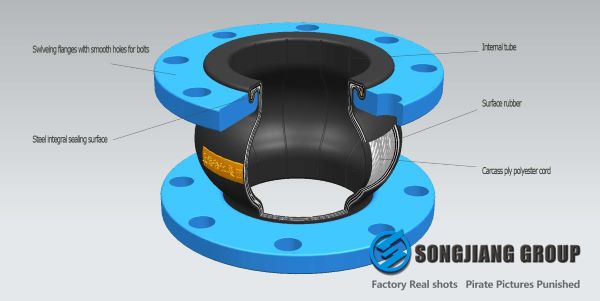

The function of the Pipeline rubber bellow is to dampen and reduce noise, and to compensate the displacement of the pipeline in the axial, radial and angular directions. The oil-resistant Pipeline rubber bellow cannot be fused with oil, which can prolong the service life and transport oily liquids. The oil-resistant Pipeline rubber bellow is derived from the product The characteristics of the requirements for the rubber part.

Related Links: Single Sphere Pipeline Expansion Joint

If the original article is reprinted, please indicate the link of this article:https://www.pipeline-expansion-joint.com/how-to-use-and-install-the-pipeline-rubber-bellows-for-pipes.html

![[304] Stainless Steel Flanged Pipeline Expansion Joint DN150 “Lined with PTFE”](https://pipeline-expansion-joint.com/wp-content/uploads/2022/05/PTFE-Lined-Single-Sphere-Rubber-Joint-SUS304EPDMPTFE-3.jpg)

![[PTFE] Pipeline Expansion Joint “High lubricating and non-sticky”](https://pipeline-expansion-joint.com/wp-content/uploads/2022/05/PTFE-Pipeline-Expansion-Joint-Photo.jpg)

![[Xingyang Longcheng Experimental School Project] EPDM pipeline expansion joint Contract](https://www.pipeline-expansion-joint.com/wp-content/uploads/2022/05/Xingyang-Longcheng-Experimental-School-Project.jpg)