Shanghai Songjiang Group which specializes in manufacturing pipline expansion joints and spring vibration isolators introduces “The PLA 7431 Factory”, also known as the Guangdong Yunshan Automobile Factory, operates under the Southern Theater Command Equipment Department of the PLA. Located at 261 Bingfang Street, Airport Road, Baiyun District, Guangzhou, this state-owned military enterprise covers over 200,000 square meters. It holds the status of a second-class national enterprise and a first-class military enterprise, employing around 120 personnel. The factory’s core functions include major and medium repairs of vehicles for the Southern Theater Command, as well as offering local vehicle repair services. It also engages in expanding its equipment repair services, producing and selling starter lead-acid batteries, and developing property leasing and other tertiary industries.

Equipment Maintenance and Upgrades at the PLA 7431 Factory

In the daily operations of the factory, equipment maintenance and upgrades are crucial to ensuring continuous efficient operation. In recent years, the factory has undertaken a series of equipment upgrades and production line renovations aimed at improving production efficiency and product quality. Reliability and durability are key factors in selecting equipment components for these projects. For this round of equipment upgrades, the factory chose to use NBR oil-resistant pipeline expansion joints produced by Shanghai Songjiang Group.

Features and Advantages of NBR Oil-Resistant Pipeline Expansion Joints

NBR (Nitrile Butadiene Rubber) oil-resistant pipeline expansion joints exhibit superior performance in various aspects, making them particularly suitable for industrial environments involving equipment connections and piping systems. Here are their main features and advantages:

- Excellent Oil Resistance: NBR has outstanding oil resistance, effectively withstanding various oils and fats. Its chemical structure contains nitrile groups, which allow NBR to maintain good physical properties in oily environments, preventing the joint material from aging and deteriorating due to oil corrosion.

- Economic Efficiency: Compared to traditional mechanical expansion and packing damping devices, NBR pipeline expansion joints take up less space, are lighter in weight, easy to install and dismantle, and save on labor and time costs. Their smooth inner wall reduces fluid resistance and prevents damage to pipe components. They have excellent water tightness and do not require additional gaskets, with a wide range of applications.

- Displacement Adaptability: NBR pipeline expansion joints are highly elastic, effectively adapting to compression, stretching, twisting, and lateral displacement, preventing damage to the pipeline system due to thermal expansion and contraction or uneven foundation settlement.

- Temperature Resistance: With a reasonable material formulation, NBR pipeline expansion joints can operate within a temperature range of -20℃ to 120℃, making them suitable for various harsh temperature environments, with a lifespan of up to 5 years or more indoors.

- Ease of Installation: NBR pipeline expansion joints are compact and lightweight, making them easy to install and maintain. Their flexibility and durability make them perform exceptionally well in various industrial piping systems.

Application in the PLA 7431 Factory

During the equipment upgrades at the PLA 7431 Factory, NBR oil-resistant pipeline expansion joints were extensively used in various oil and fat media transport pipelines. These pipeline systems are susceptible to high temperatures, oil substances, and mechanical vibrations. Traditional materials often fail to maintain stable operation over extended periods. By using NBR oil-resistant pipeline expansion joints, the factory effectively addressed these issues, ensuring the reliability and safety of the pipeline systems.

Specific Application Scenarios include:

- Vehicle Maintenance Equipment: NBR pipeline expansion joints effectively resist the erosion of oil lubricants in vehicle maintenance and servicing equipment, extending equipment lifespan.

- Hydraulic Systems: NBR pipeline expansion joints in hydraulic systems resist hydraulic oil corrosion, maintaining system seal integrity and stability.

- Engine Systems: In engine-related equipment, NBR pipeline expansion joints can withstand high temperatures and oily environments, ensuring engine reliability.

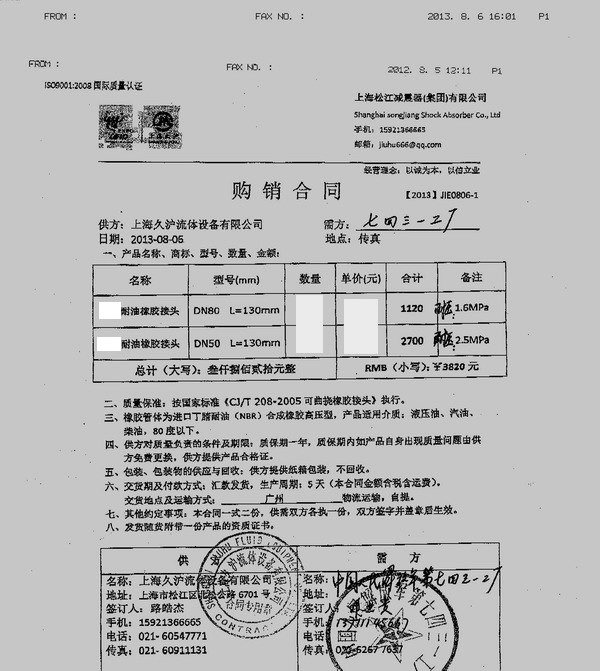

Below is a scanned copy of the authentic contract. Please do not modify or reproduce it. This contract serves as proof of supply. Thank you for your cooperation.

Feedback and Conclusion

Since incorporating NBR oil-resistant pipeline expansion joints from Shanghai Songjiang Group, the PLA 7431 Factory has reported marked improvements in equipment efficiency, reduced failure rates, and better control over maintenance costs. The factory has praised these products for their excellent oil resistance and long-term durability.

In summary, NBR oil-resistant pipeline expansion joints have proven to be a reliable solution for the PLA 7431 Factory’s equipment maintenance and upgrades. Their outstanding oil resistance, cost-effectiveness, adaptability to displacement, and temperature resilience have ensured continuous efficient operations even in harsh environments. Shanghai Songjiang Group’s high-quality NBR pipeline expansion joints have significantly enhanced the factory’s operational stability and productivity.

Related links:[ANSI] Water Pump Rubber Expansion Joints “Physical factory”

If the original article is reprinted, please indicate the link of this article:https://www.pipeline-expansion-joint.com/nbr-oil-resistant-pipeline-expansion-joints-at-pla-7431-factory.html

![[ANSI] Flange Pipeline Expansion Joint Price List](https://pipeline-expansion-joint.com/wp-content/uploads/2022/05/ANSI-flanged-high-pressure-pipeline-expansion-Joints-Product-Photo.jpg)

![[EPDM] Pipeline Expansion Joints“Ageing Resistance”](https://pipeline-expansion-joint.com/wp-content/uploads/2022/05/EPDM-Pipeline-Expansion-Joints-product-photo.jpg)

![[Rubber Joint Contract for the Expansion Project of GAC Toyota New Energy]](https://www.pipeline-expansion-joint.com/wp-content/uploads/2025/02/Rubber-Isolators-for-the-Expansion-Project-of-GAC-Toyota-New-Energy.jpg)