In the realm of industrial renovations, enhancing shower systems within factories is pivotal for ensuring operational efficiency and safety. This case study explores the Wuhan Shenlong No.1 Factory’s shower renovation project, emphasizing the crucial role played by pipeline expansion joints in augmenting the system’s functionality.

Pipeline Expansion Joints: Key Components for Shower System Renovations

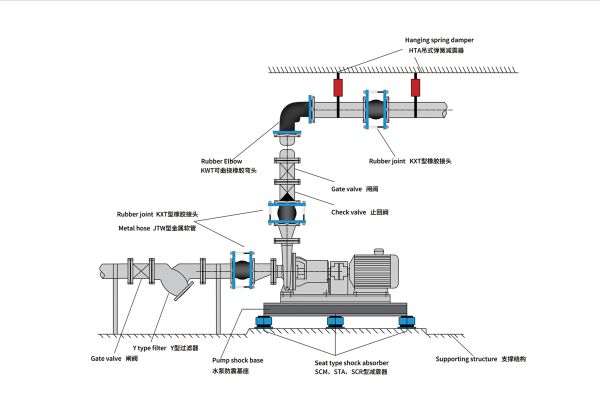

Pipeline expansion joints serve as indispensable components in factory shower system renovations. Their versatile functionality addresses several critical aspects:

Temperature Variations Management:

Industrial shower systems frequently encounter temperature fluctuations. Pipeline expansion joints effectively absorb thermal expansion and contraction, thereby mitigating stress on the pipeline system. This capability ensures pipeline integrity, preventing damage due to temperature-induced expansion.

Vibration and Impact Dampening:

Machinery operations in industrial settings can generate vibrations and impacts. Pipeline expansion joints efficiently absorb these vibrations and shocks, minimizing their transmission to the shower system pipelines. This reduces noise levels and prevents potential damage caused by excessive vibration.

Compensation for Misalignment and Installation Errors:

During shower system installation, misalignments and errors may occur. Pipeline expansion joints, with their flexible design and ability to accommodate movement, compensate for such deviations. This ensures secure connections and optimal sealing performance of the pipeline system.

Prolonging Pipeline Lifespan:

By alleviating stress and minimizing the impact of vibrations, pipeline expansion joints contribute to extending the lifespan of pipeline systems. This reduces maintenance costs and enhances operational efficiency by minimizing downtime associated with repairs and replacements.

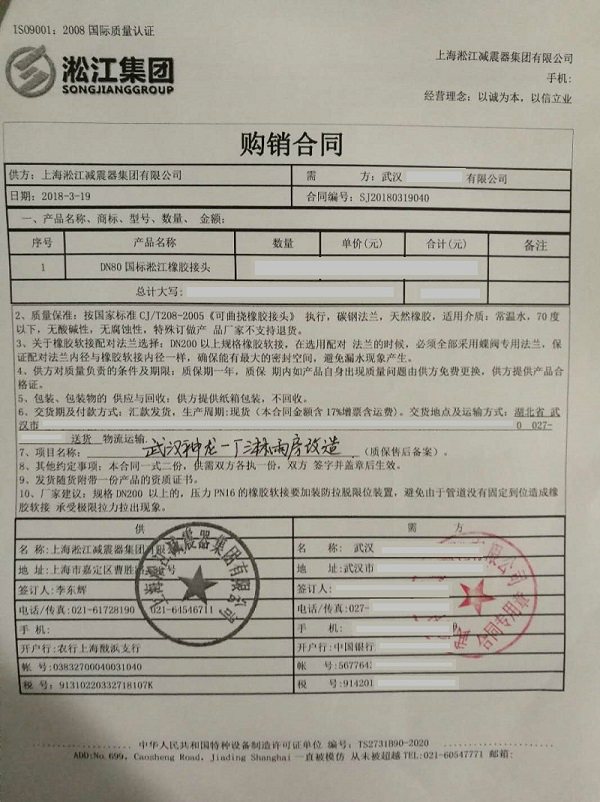

Case Study: Wuhan Shenlong No.1 Factory Shower Renovation Project

The Wuhan Shenlong No.1 Factory embarked on a comprehensive shower renovation project to enhance operational efficiency and ensure employee well-being. A critical aspect of this project was the installation of pipeline expansion joints within the shower system pipelines. These joints were strategically placed to address temperature fluctuations, dampen vibrations, and compensate for any misalignments or installation errors.

Below is a scanned copy of the authentic contract. Please do not modify or reproduce it. This contract serves as proof of supply. Thank you for your cooperation.

In conclusion,The successful renovation of the Wuhan Shenlong No.1 Factory’s shower system underscores the significance of incorporating pipeline expansion joints in industrial infrastructure projects. By effectively managing temperature variations, dampening vibrations, and compensating for installation errors, these joints play a pivotal role in enhancing the functionality and longevity of factory shower systems. As industries prioritize operational efficiency and workplace safety, the utilization of pipeline expansion joints in shower system renovations emerges as a recommended practice for achieving these objectives.

Related links:[KXT-PVC-EPDM] Pipeline Expansion Joint DN100

If the original article is reprinted, please indicate the link of this article:https://www.pipeline-expansion-joint.com/optimizing-factory-shower-systems-with-pipeline-expansion-joints-a-case-study.html

![[PVC Flange] Double Sphere Pipeline Expansion Joint](https://pipeline-expansion-joint.com/wp-content/uploads/2022/05/PVC-Flange-Double-Sphere-Pipeline-Expansion-Joint.jpg)

![[ANSI] Flange Pipeline Expansion Joint Price List](https://pipeline-expansion-joint.com/wp-content/uploads/2022/05/ANSI-flanged-high-pressure-pipeline-expansion-Joints-Product-Photo.jpg)

![[Jiangsu Runyang Yueda Photovoltaic] pipeline expansion joint Contract “Butterfly valve special flange”](https://pipeline-expansion-joint.com/wp-content/uploads/2022/05/Jiangsu-Runyang-Yueda-Photovoltaic-pipeline-expansion-joint-Contracts.jpg)

![[Spring Vibration Isolator Contract for Cold and Heat Source Main Unit Project of Chongqing International Airport Terminal T3B]](https://www.pipeline-expansion-joint.com/wp-content/uploads/2025/02/Shock-Absorbers-of-Chongqing-International-Airport.jpg)