When it comes to industrial systems that deal with extreme temperatures, pressures, and corrosive environments, the choice of components is critical. Rubber expansion joints lined with polytetrafluoroethylene (PTFE) offer a powerful solution to enhance durability and performance in such conditions. In this article, we will explore what makes PTFE-lined rubber expansion joints an excellent choice for various applications.

PTFE-lined rubber expansion joints provide superior protection against high temperatures, corrosion, and vibration. These expansion bellows ensure the longevity and stability of your systems, making them ideal for industries like chemical processing, power plants, and aerospace. The use of PTFE significantly improves the performance of rubber expansion joints, offering enhanced resistance and sealing capabilities.

Now, let’s dive into the specific advantages and applications of PTFE-lined rubber expansion joints to understand why they are the preferred choice for critical industrial systems.

What is a Rubber Expansion Joint Lined with PTFE?

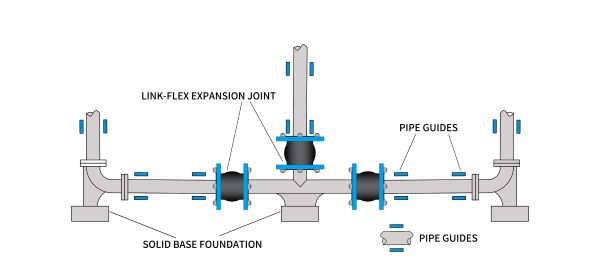

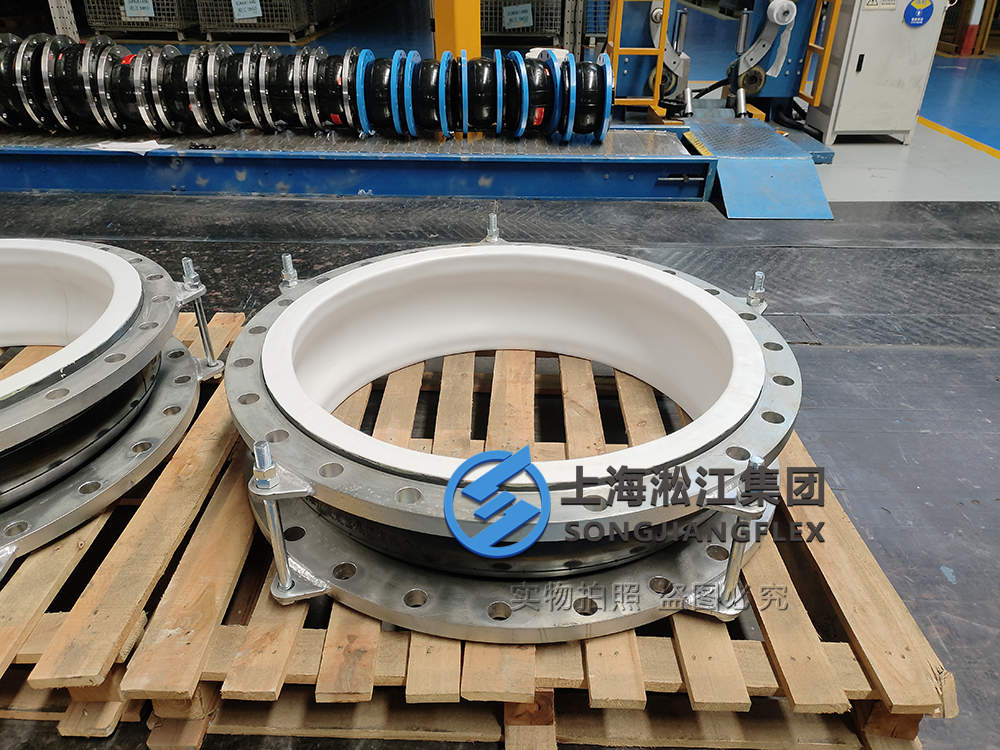

A rubber expansion joint lined with PTFE is an advanced type of flexible connector designed to absorb vibration, thermal expansion, and misalignment in piping systems. The PTFE lining adds an extra layer of protection to the rubber, enhancing its resistance to high temperatures and aggressive chemicals.

A PTFE expansion joint is a rubber bellow expansion joint that features a PTFE liner, providing superior resistance to corrosion and chemical attacks. This makes them ideal for applications where standard rubber expansion joints might fail due to harsh operating conditions.

PTFE-lined rubber expansion joints are constructed by combining a durable rubber bellows with a PTFE liner, offering the best of both materials. The rubber bellows provide flexibility and resilience, while the PTFE liner adds resistance to harsh environments, such as chemical, acid, or high-temperature conditions. This combination ensures that PTFE expansion joints can last longer in industries like chemical processing, petrochemical, and power plants.

What Are the Applications of PTFE-Lined Rubber Expansion Joints?

PTFE-lined rubber expansion joints are used in various industrial applications where the need for flexibility, durability, and resistance to harsh environments is critical.

These expansion joints are widely used in industries such as chemical processing, petroleum, power generation, and aerospace. Their resistance to chemicals, high temperatures, and vibrations makes them versatile and highly effective in challenging environments.

In the chemical industry, PTFE-lined rubber expansion joints are used to protect piping systems from aggressive chemicals. In power plants, they handle the thermal expansion and vibrations of steam and hot water pipes. In aerospace, PTFE-lined expansion bellows are used to maintain the integrity of critical components exposed to high pressure and temperature changes.

How to Maintain PTFE-Lined Rubber Expansion Joints?

Proper maintenance of PTFE-lined rubber expansion joints is essential to ensure their continued performance and longevity.

Regular inspection and maintenance of PTFE expansion joints are crucial to avoid issues such as wear, leaks, or reduced flexibility. Cleaning and checking for signs of damage can prevent costly repairs and downtime.

Maintenance for PTFE-lined rubber expansion joints involves routine inspections to check for cracks, leaks, or signs of wear. It’s also essential to ensure that the joint is not exposed to temperatures or chemicals beyond its rated limits. In some cases, cleaning with mild detergents and lubricating the bellows can help maintain their flexibility and performance.

What is the Difference Between Rubber Expansion Joints and Metal Expansion Joints?

Rubber and metal expansion joints are both used to accommodate thermal expansion and vibration, but they differ significantly in their construction and performance characteristics.

Rubber expansion joints are more flexible and can absorb larger movements, while metal expansion joints are more durable and resistant to high pressure. PTFE-lined rubber expansion joints combine the best features of both materials.

Rubber expansion joints are typically used in systems where flexibility and vibration absorption are crucial, while metal expansion joints are more suitable for high-pressure, high-temperature applications. PTFE-lined rubber expansion joints provide a balance of flexibility and durability, making them suitable for a wide range of industrial applications.

Summary

PTFE-lined rubber expansion joints offer enhanced performance, durability, and resistance to extreme conditions, making them the preferred choice for many industrial applications.

If the original article is reprinted, please indicate the link of this article:https://www.pipeline-expansion-joint.com/rubber-expansion-joint-lined-with-polytetrafluoroethylene-ptfe.html

![[Flange Type] Stainless Steel Metal Hose “Food Grade”](https://www.pipeline-expansion-joint.com/wp-content/uploads/2022/05/Flange-Type-Stainless-Steel-Metal-Hose-1.jpg)

![[PVC Flange] Double Sphere Pipeline Expansion Joint](https://pipeline-expansion-joint.com/wp-content/uploads/2022/05/PVC-Flange-Double-Sphere-Pipeline-Expansion-Joint.jpg)

![[Eccentric Reducer] Pipeline Expansion Joint](https://pipeline-expansion-joint.com/wp-content/uploads/2022/05/Eccentric-Reducer-Pipeline-Expansion-Joint.jpg)