[Shaanxi Longmen Steel Plant Sintering Machine Transformation Project] Pipeline Expansion Joint Contract

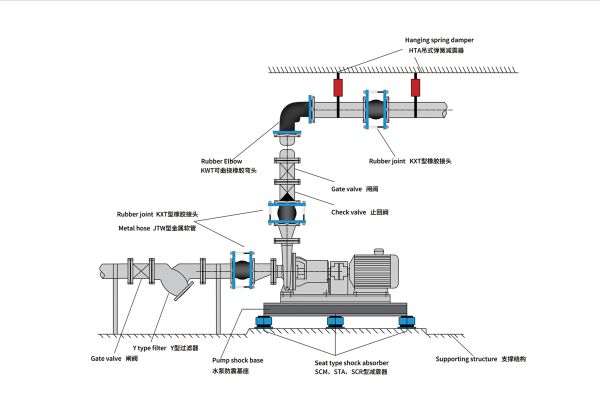

The official website of Shanghai Songjiang Group will introduce to you: [Shaanxi Longmen Steel Plant Sintering Machine Transformation Project] Pipeline Expansion Joint contract information, Songjiang Group provides desulfurized Pipeline Expansion Joints for the transformation of sintering machines in many iron and steel enterprises, this product has acid resistance, high temperature resistance and wear resistance.

Shaanxi Longmen Steel Plant Sintering Machine Transformation Project Introduction

Shaanxi Longmen Iron and Steel Group is located in Longmen Metallurgical Industrial Park, Hancheng City. The group has now formed a complete industrial chain from iron ore mining, sintering, iron making to steel making, steel rolling, power generation, hotels, logistics, transportation, etc., and completed Hancheng as a steel production base and Xi’an as a steel sales center , the strategic layout of taking southern Shaanxi as the iron ore production base. There are four 1280M3 iron-making blast furnaces, one 450M3 blast furnace, one 450M2.400M2 sintering machine, one 265M2 sintering machine, two 120-ton steelmaking converters, three 60-ton steelmaking converters, and more than ten sets of bar and wire rod rolling mills. The steel production capacity is 7 million tons, and the operating income is more than 30 billion yuan. According to the group’s development plan, by the end of the “Twelfth Five-Year Plan”, the comprehensive production capacity of Longgang Group will reach more than 10 million tons, and the operating income will reach more than 60 billion yuan.

Retrofit of electrostatic precipitator for sintering head.

Project overview: In 2008, the 265㎡ sintering machine system was newly built with a double-chamber and three-electric field 280㎡ head electrostatic precipitator; in 2011, the poles of the first and second electric fields were replaced; ) were modified to add an electric field to become the current two-chamber four-electric field. At present, there are defects in the design of the precipitator itself (beamless frame structure;) serious air leakage from the electrostatic precipitator box, insufficient power supply capacity and low dust removal efficiency, etc., which cause the outlet emissions to fail to meet the standard. Major renovation; a single-chamber four-electric-field precipitator will be built on the north side of 265 sintering, and the main part of the existing precipitator (above the power distribution room) will be dismantled step by step after being put into operation. Reinstall the dust collector system.

The electrostatic precipitator shall be modified and installed according to the dust content at the entrance of 3g/Nm3, the flue gas temperature less than 150℃, the dust content at the exit of ≤40mg/Nm3, and the dust removal efficiency of not less than 97.33%.

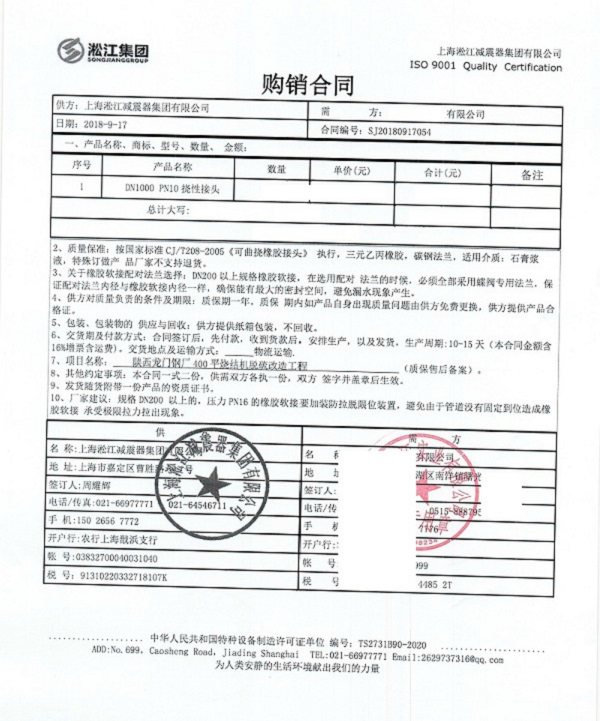

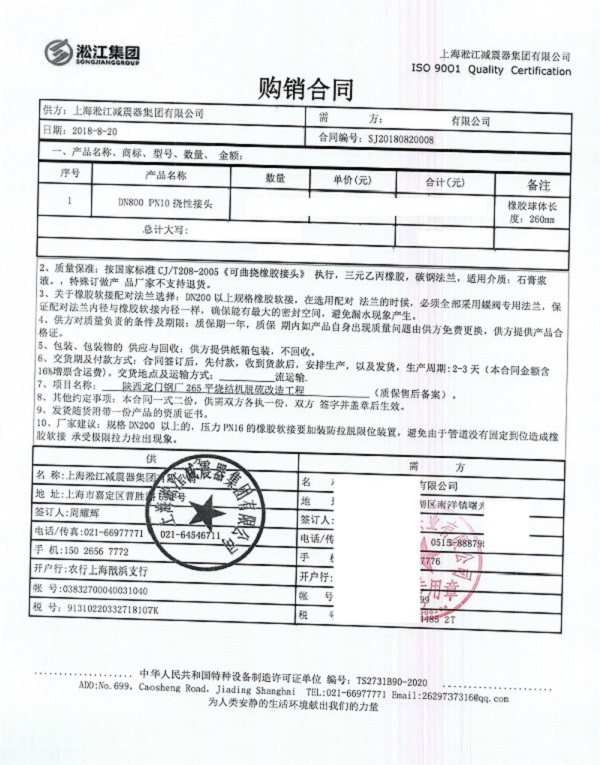

[Shaanxi Longmen Steel Plant Sintering Machine Transformation Project] Pipeline Expansion Joint Contract Introduction

The following is a scanned copy of the authenticity contract, please do not modify, please do not reprint, this contract is only as a proof of supply, thank you for your cooperation.

[Shaanxi Longmen Steel Plant Sintering Machine Transformation Project] Pipeline Expansion Joints Products Introduction

Related links: [EPDM] Pipeline Expansion Joints“Ageing Resistance”

If the original article is reprinted, please indicate the link of this article:https://www.pipeline-expansion-joint.com/shaanxi-longmen-steel-plant-sintering-machine-transformation-project-pipeline-expansion-joint-contract.html

![[JIS] Pipeline Expansion Joint “Fully Automatic Production”](https://pipeline-expansion-joint.com/wp-content/uploads/2022/05/JIS-Pipeline-Expansion-Joint-Fully-Automatic-Production-1.jpg)

![[NBR] Pipeline Expansion Joint “Good Oil-Resistant”](https://pipeline-expansion-joint.com/wp-content/uploads/2022/05/Good-Oil-Resistant-NBR-Pipeline-Expansion-Joint-Photo.jpg)

![[Rubber Joint Contract for the Expansion Project of GAC Toyota New Energy]](https://www.pipeline-expansion-joint.com/wp-content/uploads/2025/02/Rubber-Isolators-for-the-Expansion-Project-of-GAC-Toyota-New-Energy.jpg)