Guangzhou GAC Toyota Automotive Factory is a hallmark of innovation and precision in the automotive industry. To uphold its standards of operational efficiency and equipment reliability, the factory has integrated Songjiang Pipeline Expansion Joints into its critical systems. These meticulously engineered components provide essential flexibility and durability, ensuring smooth functionality and enhanced performance within the factory’s complex pipeline networks.

Installation Process:

The installation of Songjiang Pipeline Expansion Joints at Guangzhou GAC Toyota Automotive Factory follows a comprehensive and tailored approach. Expert technicians work closely with the factory’s engineering team to identify optimal installation points within various pipeline systems. Each expansion joint is precisely installed to accommodate thermal expansion, vibration, and movement, thereby minimizing stress on the connected components and ensuring seamless operation.

Application Details:

Songjiang Pipeline Expansion Joints are utilized in several key areas within the factory, including:

Cooling Systems: In the cooling systems, these expansion joints absorb thermal expansion and contraction, preventing undue stress on the pipelines and maintaining consistent performance. This ensures that the cooling systems operate efficiently, safeguarding the equipment from overheating.

Hydraulic Systems: Within hydraulic systems, Songjiang Pipeline Expansion Joints facilitate smooth fluid flow while minimizing pressure fluctuations. This contributes to the overall reliability and efficiency of the hydraulic systems, which are crucial for various manufacturing processes.

Exhaust Systems: In the exhaust systems, these expansion joints effectively absorb vibrations and movements generated by engine operations. This reduces noise levels and extends the lifespan of exhaust components, aligning with the factory’s commitment to sustainability and quality.

Key Features and Benefits:

Durability and Reliability: Crafted from high-quality materials, Songjiang Pipeline Expansion Joints offer exceptional durability and reliability, ensuring optimal performance in demanding industrial environments.

Flexibility and Adaptability: Designed to accommodate various types of movement, including thermal expansion and mechanical vibrations, these expansion joints enhance the overall stability and integrity of the pipeline systems.

Seamless Integration: Engineered for easy integration into existing pipeline networks, Songjiang Pipeline Expansion Joints minimize installation downtime and facilitate smooth operation, contributing to enhanced efficiency and productivity within the factory.

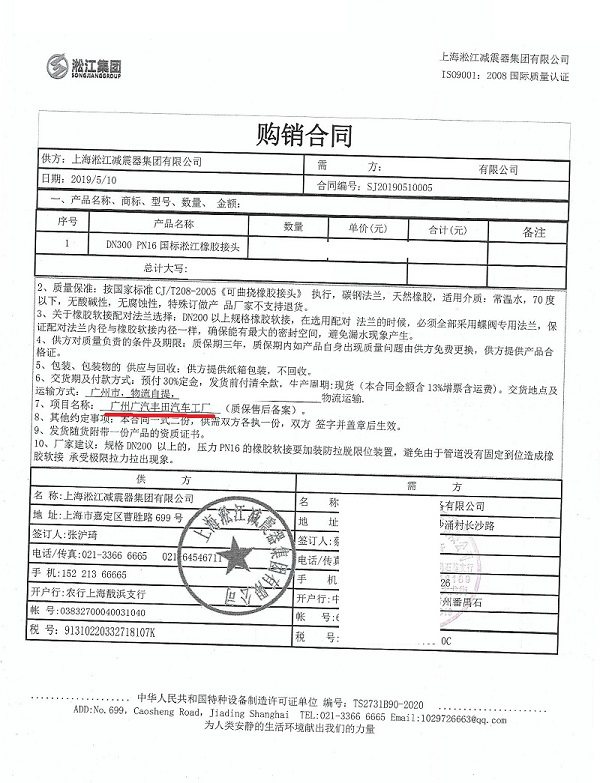

Below is a scanned copy of the authentic contract. Please do not modify or reproduce it. This contract serves as proof of supply. Thank you for your cooperation.

The successful implementation of Songjiang Pipeline Expansion Joints at Guangzhou GAC Toyota Automotive Factory underscores the importance of quality and reliability in industrial applications. By providing durable, flexible, and seamlessly integrated solutions, these expansion joints play a crucial role in maintaining the efficiency and functionality of the factory’s critical systems. At Shanghai Songjiang Vibration Absorber, we remain committed to delivering innovative solutions that exceed expectations and drive positive outcomes for our valued partners.

Related links:[KXT-PVC-EPDM] Pipeline Expansion Joint DN100

If the original article is reprinted, please indicate the link of this article:https://www.pipeline-expansion-joint.com/songjiang-pipeline-expansion-joints-at-guangzhou-gac-toyota-automotive-factory.html

![[Clamp] pipeline expansion joints “instead of flanges”](https://pipeline-expansion-joint.com/wp-content/uploads/2022/05/Clamp-Pipeline-Expansion-Joint.jpg)

![[EPDM] Pipeline Expansion Joints“Ageing Resistance”](https://pipeline-expansion-joint.com/wp-content/uploads/2022/05/EPDM-Pipeline-Expansion-Joints-product-photo.jpg)

![[DIN] Pipeline Expansion Joint “good compression resistance”](https://pipeline-expansion-joint.com/wp-content/uploads/2022/05/DIN-Pipeline-Expansion-Joint-Product-Photo-1.jpg)

![[Australia Rocklands Copper Mine Project] anti-radiation pipeline rubber bellows Ready for dispatch](https://pipeline-expansion-joint.com/wp-content/uploads/2022/05/Australia-Rocklands-Copper-Mine-Project-Radiation-proof-pipeline-expansion-joint-Product-2.jpg)

![[Rubber Joint Contract for the Expansion Project of GAC Toyota New Energy]](https://www.pipeline-expansion-joint.com/wp-content/uploads/2025/02/Rubber-Isolators-for-the-Expansion-Project-of-GAC-Toyota-New-Energy.jpg)