The official website of Shanghai Songjiang Vibration Isolator Group Co., Ltd. presents to you the relevant information regarding the [Spring Vibration Isolator Contract for Cold and Heat Source Main Unit Project of Chongqing Jiangbei International Airport Terminal T3B]. Leveraging its professional expertise and extensive experience in the field of vibration isolation, Shanghai Songjiang Group has provided high – performance adjustable spring vibration isolators for cold and heat source main units and machine room projects of numerous terminal buildings and runway projects. These spring vibration isolators are manufactured from high – quality steel, boasting excellent elasticity and durability. They can effectively absorb and disperse vibration energy, achieving outstanding noise and vibration isolation effects. Additionally, the group has supplied pipeline vibration isolator products to Beijing Daxing Airport, establishing a good reputation in the industry with its high – quality products and services. The following is an introduction to the contract information of the spring vibration isolators for the procurement project of cold and heat source main units and machine room group control of Chongqing Jiangbei International Airport Terminal T3B and the fourth runway project.

- Bidding Conditions The project of Chongqing Jiangbei International Airport Terminal T3B and the fourth runway has been approved for construction by the National Development and Reform Commission through Document No. [2020] 1721 of the National Development and Reform Commission. The project owner is Chongqing Airport Group Co., Ltd., and the construction funds are sourced from the National Development and Reform Commission, the Civil Aviation Administration of China, the People’s Government of Chongqing Municipality, and the self – raised funds of Chongqing Airport Group Co., Ltd. Currently, the project has met the bidding conditions, and a public tender is now being carried out for the procurement project of cold and heat source main units and machine room group control of Chongqing Jiangbei International Airport Terminal T3B and the fourth runway project.

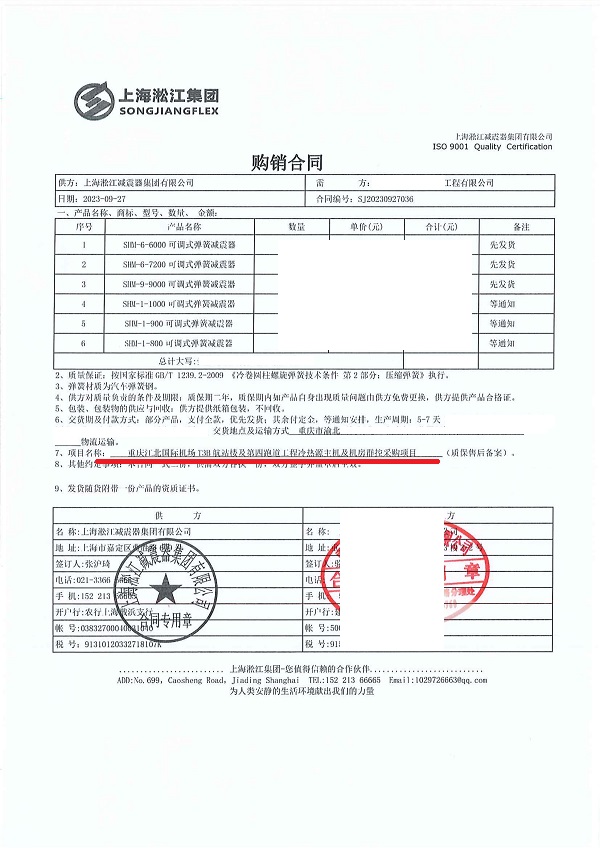

III. Product Diagram of the Spring Vibration Isolator Contract for the Procurement Project of Cold and Heat Source Main Units and Machine Room Group Control of Chongqing Jiangbei International Airport Terminal T3B and the Fourth Runway Project

If the original article is reprinted, please indicate the link of this article:https://www.pipeline-expansion-joint.com/spring-vibration-isolator-contract-for-cold-and-heat-source-main-unit-project-of-chongqing-international-airport-terminal-t3b.html

![[Elbow] pipeline expansion joint “PVC/ Stainless Steel Flange”](https://pipeline-expansion-joint.com/wp-content/uploads/2022/05/Elbow-pipeline-expansion-joint-PVC-Stainless-Steel-Flange.jpg)

![[KXT-PVC-EPDM] Pipeline Expansion Joint DN100](https://pipeline-expansion-joint.com/wp-content/uploads/2022/05/KXT-Type-Pipeline-Expansion-Joint-1.jpg)

![[Rubber Joint Contract for the Expansion Project of GAC Toyota New Energy]](https://www.pipeline-expansion-joint.com/wp-content/uploads/2025/02/Rubber-Isolators-for-the-Expansion-Project-of-GAC-Toyota-New-Energy.jpg)

![[Australia Rocklands Copper Mine Project] anti-radiation pipeline rubber bellows Ready for dispatch](https://pipeline-expansion-joint.com/wp-content/uploads/2022/05/Australia-Rocklands-Copper-Mine-Project-Radiation-proof-pipeline-expansion-joint-Product-2.jpg)