In the intricate tapestry of industrial endeavors, the IOI Xiamen Oil Project stands as a testament to innovation and operational excellence. Central to the success of this venture lies the strategic integration of metal hoses, facilitated by the partnership between Shanghai Songjiang Vibration Absorber Group Co., Ltdwhich specializes in manufacturing pipeline expansion joints and spring vibration isolators . and IOI (Xiamen) Oil Technology Co., Ltd. These metal hoses, meticulously engineered and deployed within the project’s infrastructure, play a pivotal role in optimizing efficiency and ensuring seamless production processes.

At the heart of the IOI Xiamen Oil Project’s operations lies the imperative need for reliable fluid transmission systems.Songjiang Metal hoses, as exemplified in their utilization within the project, serve as the linchpin for conveying various media critical to the oil and fat industry. From transporting raw oils and chemical raw materials to facilitating the transmission of finished oils, these hoses ensure the uninterrupted flow of substances essential for the project’s production processes.

Furthermore, within the sprawling expanse of the IOI Xiamen Oil Project’s facilities, metal hoses serve as indispensable connecting components of pipeline systems. By seamlessly linking equipment and pipelines, these hoses guarantee smooth fluid transmission, thereby minimizing operational disruptions and optimizing productivity. This seamless connectivity underscores the meticulous planning and engineering prowess inherent in the project’s infrastructure.

Moreover, the demanding operational environment of the oil and fat industry necessitates equipment and materials capable of withstanding corrosive effects and high temperatures. In this regard, metal hoses deployed within the IOI Xiamen Oil Project demonstrate exemplary corrosion resistance and high-temperature tolerance. Designed to endure the rigors of refining and oleochemical processes, these hoses ensure operational reliability and longevity, mitigating the risks associated with material degradation and leaks.

Beyond their functional attributes, metal hoses deployed within the IOI Xiamen Oil Project exhibit a remarkable degree of flexibility and shock absorption capabilities. This inherent flexibility enables these hoses to adapt seamlessly to spatial constraints and positional relationships within the project’s facilities, facilitating ease of installation and maintenance. Additionally, their ability to absorb shocks and minimize noise levels contributes to a conducive working environment, enhancing operational efficiency and employee well-being.

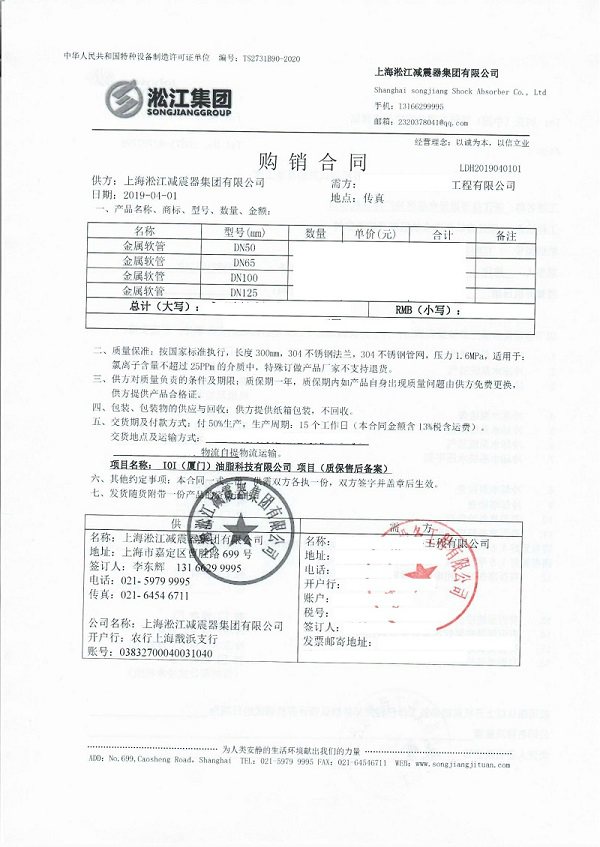

Below is a scanned copy of the authentic contract. Please do not modify or reproduce it. This contract serves as proof of supply. Thank you for your cooperation.

In summary, the successful integration of Songjiang metal hoses within the IOI Xiamen Oil Project underscores their indispensable role in optimizing operations and ensuring operational reliability. From facilitating fluid transmission and providing robust pipeline connections to exhibiting corrosion resistance, high-temperature tolerance, flexibility, and shock absorption capabilities, these hoses epitomize the pinnacle of engineering excellence in fluid transmission systems. As the project continues to evolve and innovate, the enduring legacy of metal hoses as critical components in industrial operations remains steadfast.

Related links:[Flange Type] Stainless Steel Metal Hose “Food Grade”

If the original article is reprinted, please indicate the link of this article:https://www.pipeline-expansion-joint.com/streamlining-operations-the-crucial-role-of-songjiang-metal-hoses-in-ioi-xiamen-oil-project.html

![[KXT-PVC-EPDM] Pipeline Expansion Joint DN100](https://pipeline-expansion-joint.com/wp-content/uploads/2022/05/KXT-Type-Pipeline-Expansion-Joint-1.jpg)

![[Clamp] pipeline expansion joints “instead of flanges”](https://pipeline-expansion-joint.com/wp-content/uploads/2022/05/Clamp-Pipeline-Expansion-Joint.jpg)

![[Charity Certificate]Shanghai Songjiang Group was awarded the Charity Star Enterprise Certificate](https://www.pipeline-expansion-joint.com/wp-content/uploads/2022/05/Charity-CertificateShanghai-Songjiang-Group-was-awarded-the-Charity-Star-Enterprise-Certificate-1.jpg)