Introduction of [EPDM] Pipeline Expansion Joints“Ageing Resistance”

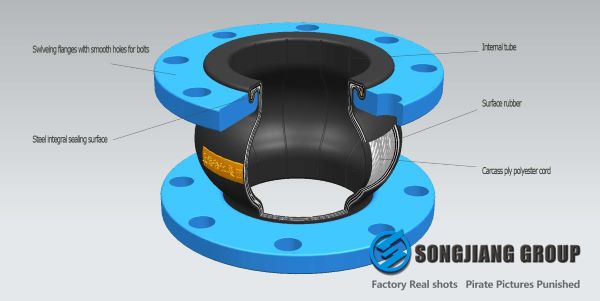

Shanghai Songjiang Group Introduce to you: EPDM Pipeline Expansion Joints “Ageing Resistance”information. EPDM Pipeline Expansion Joints have the characteristics of high-temperature resistance, acid and alkali resistance, and corrosion resistance.

EPDM Pipeline Expansion Joints are also called EPDM Rubber Bellows.

EPDM Pipeline Expansion Joints Characteristic:

EPDM rubber has excellent weather resistance, ozone resistance, heat resistance, acid and alkali resistance, water vapor resistance, color stability, electrical properties, oil-filled properties and fluidity at room temperature. EPDM Pipeline Expansion Joints can be used for a long time at 120℃, and can be used temporarily or intermittently at 150-200℃. Adding suitable antioxidants can increase its service temperature. EPDM rubber cross-linked with peroxide can be used under harsh conditions. Under the conditions of ozone concentration of 50pphm and stretching of 30%, EPDM rubber can reach more than 150h without cracking.

In the corresponding pipeline equipment, it can effectively prevent the erosion of the inner wall of the rubber joint by the corrosive medium, and effectively improve the service life.

EPDM Pipeline Expansion Joints Features:

EPDM Pipeline Expansion Joints are small in size, light in weight, good in elasticity, and easy to install and maintain.

EPDM Pipeline Expansion Joints Installation:

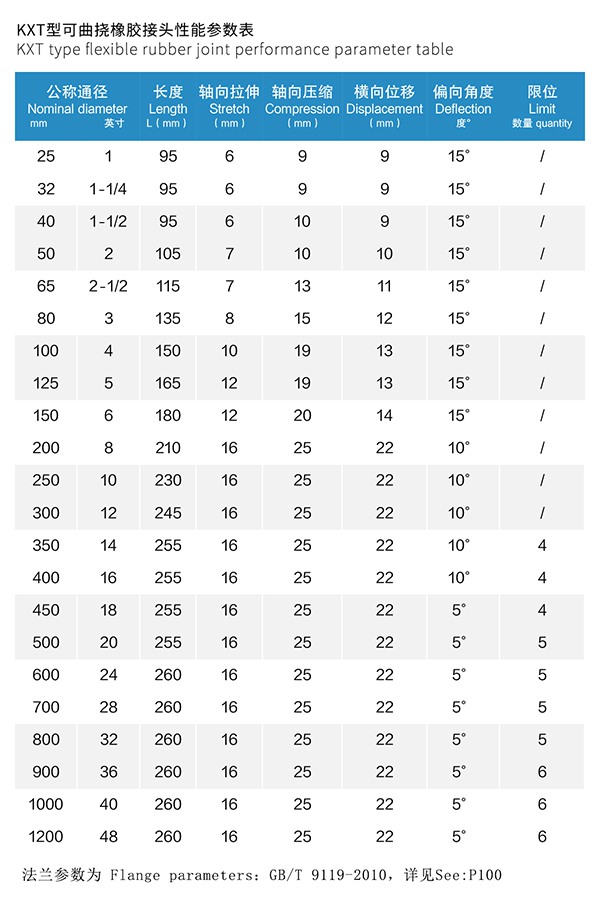

It can produce lateral, axial, and angular displacement during installation, and is not limited by the non-concentricity of the pipeline and the non-parallel flange.

EPDM Pipeline Expansion Joints Work:

When working, it can reduce the noise transmitted by the structure and has a strong vibration absorption ability.

Related Links: [NBR] Pipeline Expansion Joint “Good Oil-Resistant”

If the original article is reprinted, please indicate the link of this article:https://www.pipeline-expansion-joint.com/epdm-pipeline-expansion-jointsageing-resistance.html

![[ANSI] Flange Pipeline Expansion Joint Price List](https://pipeline-expansion-joint.com/wp-content/uploads/2022/05/ANSI-flanged-high-pressure-pipeline-expansion-Joints-Product-Photo.jpg)

![[Shanghai University Mechatronic Engineering] NBR Pipeline Expansion Joint Contract](https://www.pipeline-expansion-joint.com/wp-content/uploads/2022/05/Shanghai-University.jpg)

![[Australia Rocklands Copper Mine Project] anti-radiation pipeline rubber bellows Ready for dispatch](https://pipeline-expansion-joint.com/wp-content/uploads/2022/05/Australia-Rocklands-Copper-Mine-Project-Radiation-proof-pipeline-expansion-joint-Product-2.jpg)

![[Charity Certificate]Shanghai Songjiang Group was awarded the Charity Star Enterprise Certificate](https://www.pipeline-expansion-joint.com/wp-content/uploads/2022/05/Charity-CertificateShanghai-Songjiang-Group-was-awarded-the-Charity-Star-Enterprise-Certificate-1.jpg)